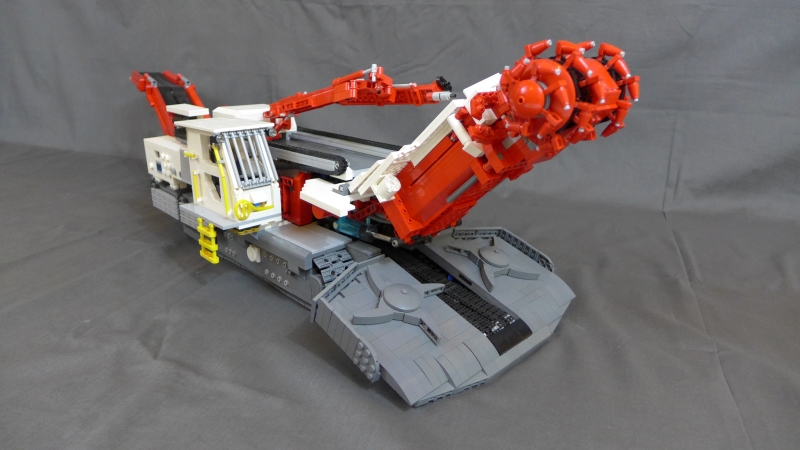

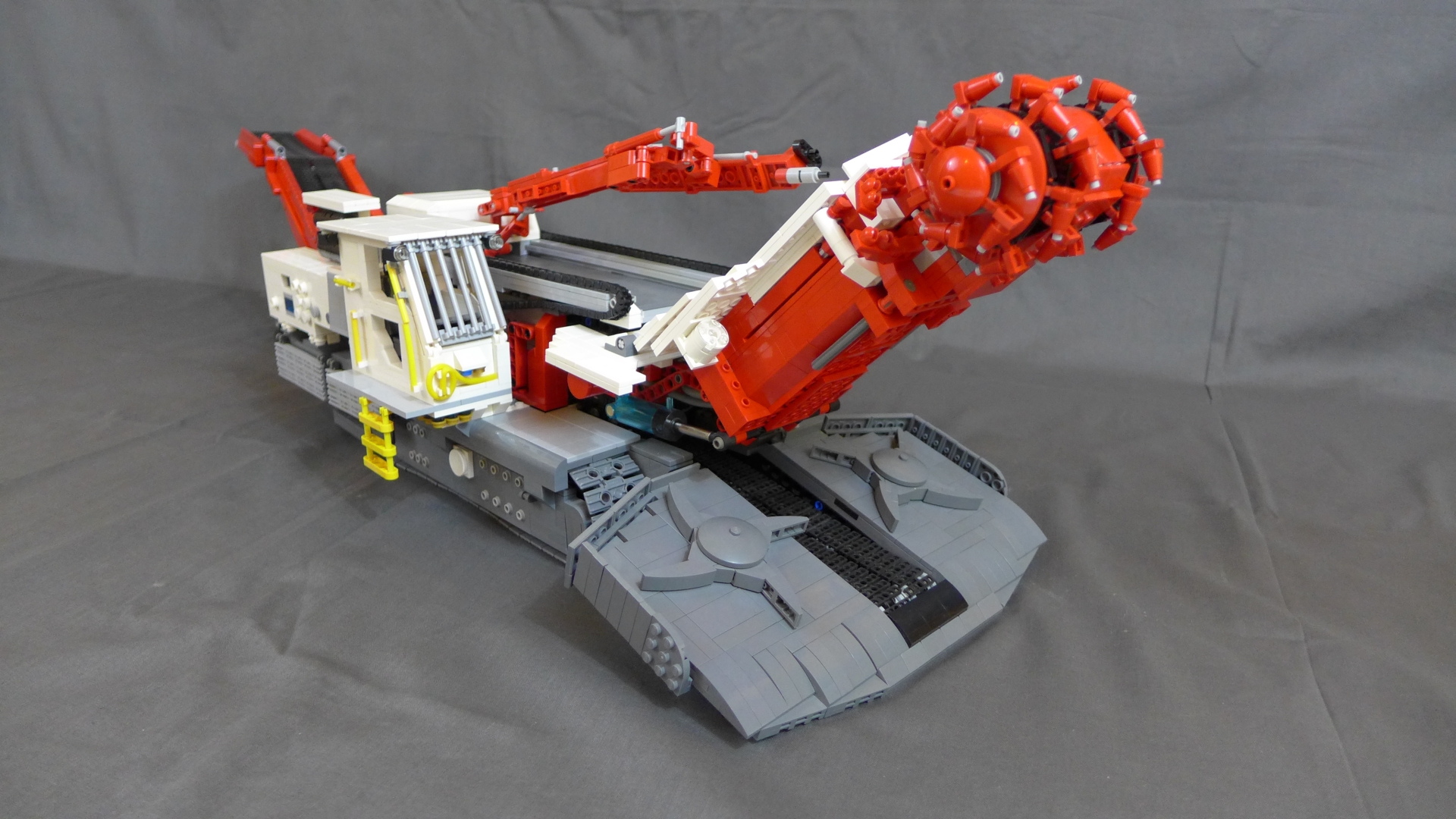

Model of a underground hard rock miner, built for Sandvik Mining for

showing at International Copper Ore Mining Congress at Sandvik

exposision hall.

Completion date: 15/09/2015

Power: electric (Power Functions), pneumatic (fed from external pump)

Dimensions: length over 120 studs / width 29studs (with cab)/ height 40 studs

Weight: over 5 kg

Suspension: none

Propulsion: PF L motor

Motors: 1 x PF L motor, 4 x M motors, 1 x 47154c01 motor

From 16th to 18th September 2015 I was at International Copper Ore Mining Congress at Sandvik exposision hall. Yes, year ago.

But now it is time to show this model, because it will be taken apart shortly 🙂

It was built in a hurry, under 3 weeks, for Sandvik exhibition .As a result of such rush it ended quite

well, but if there was much more time given, it could be much better. For example the drive system did not worked at all, becuase model was too heavy at the end of building process and there was no time for rebuilds. Anyway, it did not had too many space on the table for moving freely, so having no propulsion was no a big problem 🙂

Features six pneumatic and four motorized functions. Pneumatic system is fed from single manual pump placed on the controller:

The motors that drive conveyors and cutting head are connected to the same PF switch. Both conveyors are made with using two rows of 3L track links. Main conveyor uses 336 of them while rear one uses 270.

Main conveyor is driven by single M motor. The loading stars are driven by the conveyor, using bevel gears underneath the loading table.

comes trough new z60 turntable, which is the only mounting point for the conveyor on the chassis.

It can be rotated, a large pneumatic cylinder has enough force to swing it from side to side. Due to its weight, rear part of the chassis under the turntable has a small wheel underneath, which handles the weight of the conveyor and prevents the frame from bending:

The cutter boom can be elevated (by two large cylinders) and extended (by 11L cylinder). 47154c01 motor drives the cutter head.A single M motor is responsible for rotating the whole boom.

Stabilizng plate on the rear can be elevated (by two small cylinders).

There’s a drivetrain hidden deep in the chassis, that was supposed to drive both tracks. But as a result of building in a hurry, it is not able to move the heavy model.

A failure, but also a beautiful disaster 🙂

Pictures:

Bricksafe

Flickr

Brickshelf

Video:

I’d like to thank Sandvik for providing documentation needed for making this model 🙂